Insights into the Tunnel Industry Trends – Present and Future

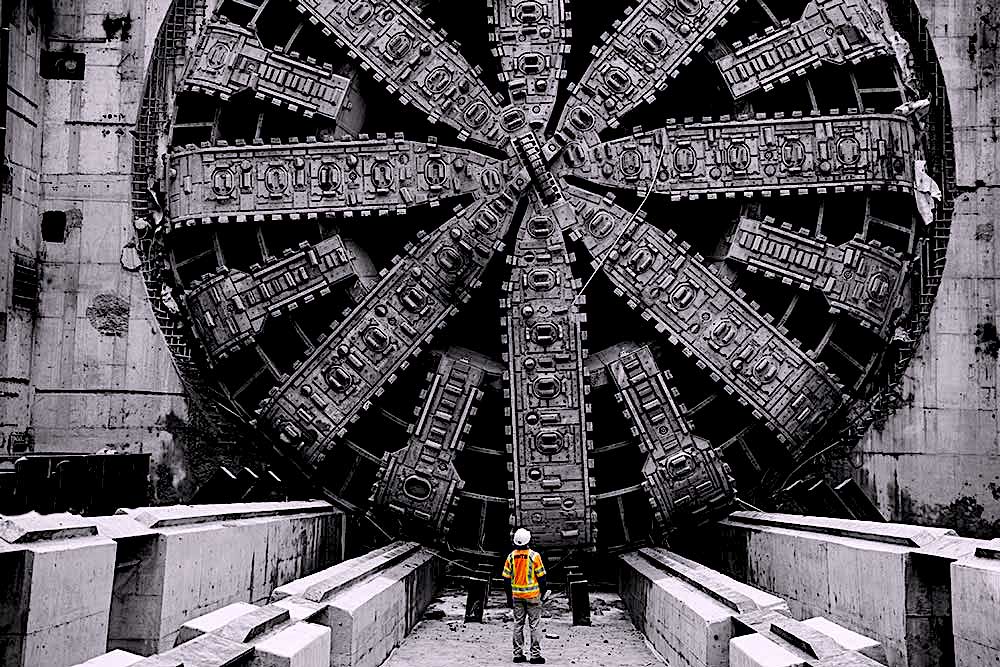

By 2050, it is anticipated that as much as 87% of the population of the United States will live in cities. We do expect this trend to be somewhat modified as a result of COVID-19 pandemic given the time the mass transportation industry needs to recover ridership and enter a ‘new normal’ operating reality. There still will be a need, however, to prepare cities and transportation agencies for implementation of less disruptive methods to minimize construction impacts to streets, utilities, businesses and communities. One way is a broader use of bored tunnels through dense urban areas.

Focus on innovations and risk-based decisions

Dealing with risks is an inherent part of the tunnel industry. Risks on tunneling projects, if not identified and well-managed, can lead to major disruptions that impact lives, properties and regional economies.

Using a well thought-through risk management approach, including implementation of an early risk register, not only defines elements and levels of risk, but also recognizes the parties that are best equipped to handle various risks through the life of a project. As part of the risk management process, it would be critical to obtain a full understanding of subsurface conditions and work on establishing the most practical and constructible project configuration in context with identified subsurface and environmental factors.

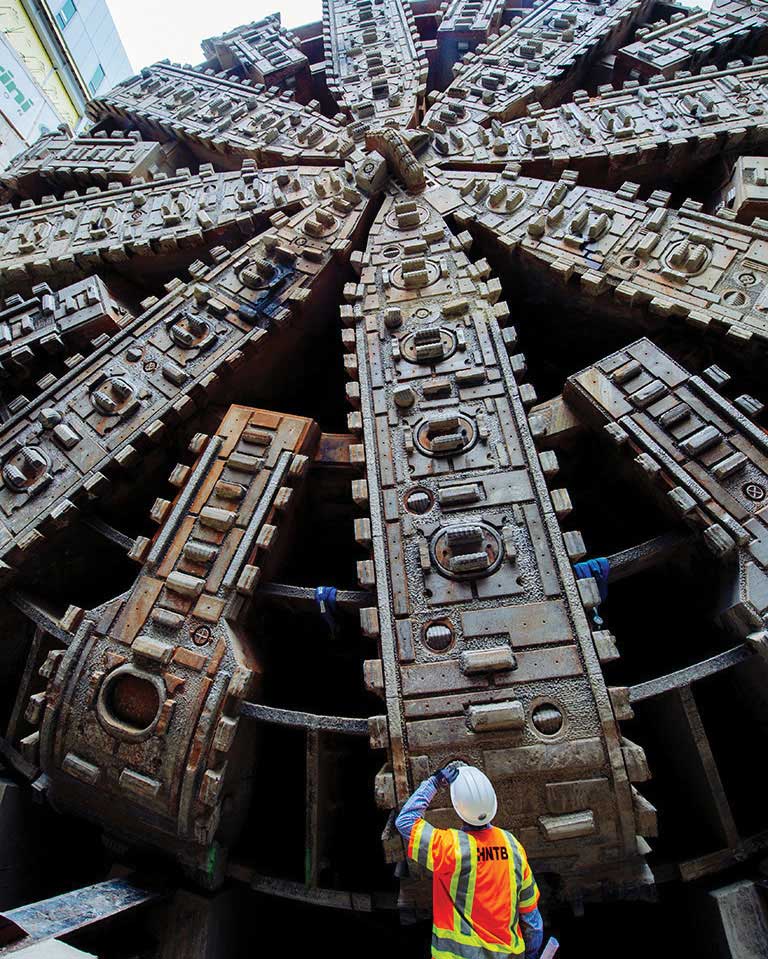

Although various project risks exist, in the last decade or so, tunneling has become safer under difficult geological and hydrological conditions. This is due to advancements in tunnel boring machine control systems and tunnel permanent support systems (liners), as well as materials and special details those entail. In fact, safety aspects in the industry have risen, and a “zero accident” policy became a quite common approach by most construction companies today. This drives the culture of safety in our industry forward. In addition, innovations in ground improvement techniques, settlement control, and the ability of tunnel boring machines to be fully pressurized allow for minimum volume losses due to excavation and minimize impacts to overlying streets, utilities and structures. Utilization of instrumentation and monitoring systems while maximizing GPS features allow for direct real-time reporting to multiple users, including owners, contractors and engineers.

Looking ahead

In the coming years, tunneling technology and processes, including tunnel boring machine control systems, materials and quality control are likely to advance further, allowing for better performances and an increase in the design service life of tunnels and underground structures in general. This expectation would further be increased by an increase in the use of public-private partnerships, where financial arms necessitate improvements in long-term maintenance and operation aspects along with general reductions in operating costs.

Additionally, the next generation of autonomous vehicles with magnetic levitation or similar systems could increase requirements for tunnels. This is due to right-of-way restrictions in urban areas that will only be met by an underground trajectory that minimizes impacts high speeds impose on passengers.

As we look ahead to the future of tunneling, implementing risk-based decision making, continued advancement of tunneling technology and approach to safety, and with development of latest technologies accommodating super high-speed mobility, paints an exciting picture for the industry moving forward.

Sanja Zlatanic, PE, is Chair-National Tunnel Practice for HNTB Corp. She has worked on some of the most complex tunnel projects domestically and internationally. With more than 32 years of experience, she has been responsible for managing all phases of multi-billion dollar underground projects, including multi-disciplinary joint venture staff, from feasibility and conceptual engineering through final design and construction.