The Metapallet is an omnimodal platform, a skid/pallet, designed for automated handling from point of origin to final destination. It is a design solution to economic development issues at all levels of the global social economy. It requires scale and mass adoption in order to meet its design goals, but that is another part of the design, as is timing.

Beginning as a simple idea for a specialty, or domestic container, the concept of the Metapallet grew as its potential was generalized to include a wide variety of commercial and domestic purposes were recognized as benefiting from its economic advantages. To better grasp the implications of an omnimodal material handling platform that can be adapted to many functions, we should look at the history of unionization and containerization.

Civilizations are frequently categorized by the standardized transportation of goods between their different trade areas. The containers found in shipwrecks and archeological digs characterize a civilization and its degree of trade efficiency, a key indicator of its success.

Once a standard is established, it is extremely difficult to change, the social and economic inertia is too great to adopt a different one without a major advantage being involved. Trade on the Mediterranean was dependent on the use of low-fire amphoras, each of which held about five gallons of oil or wine. Shipwrecks from Greek and Roman times have been found with hundreds of these amphora lining the cargo holds, their narrow bottom shape allowing a maximum number to be stowed for each voyage.

Once a standard is established, it is extremely difficult to change, the social and economic inertia is too great to adopt a different one without a major advantage being involved. Trade on the Mediterranean was dependent on the use of low-fire amphoras, each of which held about five gallons of oil or wine. Shipwrecks from Greek and Roman times have been found with hundreds of these amphora lining the cargo holds, their narrow bottom shape allowing a maximum number to be stowed for each voyage.

Later the use of wood stave barrels was adopted, but these required metal bands in order to work, so the development of brass and iron had to precede their widespread use, even though the Celts had them in 300 BC. Little changed in the centuries that followed, wood stave barrels for all manner of goods continued to the beginning of the Industrial Revolution, when the use of railroads and steam engines changed the scale of cargo to what would fit on a railroad flat car, and that was much larger than before.

Later the use of wood stave barrels was adopted, but these required metal bands in order to work, so the development of brass and iron had to precede their widespread use, even though the Celts had them in 300 BC. Little changed in the centuries that followed, wood stave barrels for all manner of goods continued to the beginning of the Industrial Revolution, when the use of railroads and steam engines changed the scale of cargo to what would fit on a railroad flat car, and that was much larger than before.

Although the evolution of technology greatly impacted transportation, the loading of goods into ships and trains change little from the time of horse-drawn carts: Strong men muscled the loads into place with the help of winches and ramps. Wooden crates grew larger but were still customized to the shipper whether it was a wagon, railroad, or ship. Steel barrels replace wood stave barrels but were still handled in a similar way. In fact, it took almost a hundred years from the time of the introduction of the steam engine to develop the forklift and pallet, and even then the loading of freight relied on the work of men on the loading docks.

Today the words “shipping container” immediately bring to mind the large steel box innovated by Malcolm McLean in the early fifties. All the prior art has been sublimated to its success as crates and barrels are now fragments of the total embraced by containerization, a concept so impacting our civilization that the period since its implementation cannot be characterized any other way. It is the age of containerization of global trade.

Today the words “shipping container” immediately bring to mind the large steel box innovated by Malcolm McLean in the early fifties. All the prior art has been sublimated to its success as crates and barrels are now fragments of the total embraced by containerization, a concept so impacting our civilization that the period since its implementation cannot be characterized any other way. It is the age of containerization of global trade.

Now the steel shipping container has made the movement of goods so much cheaper that manufacturing can be done on one side of the world while the markets for them are on the other side. The concept of scale has grown so vast that only very large companies can be involved in the trade of goods around the world.

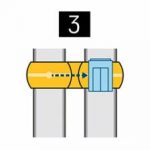

The greatest advantage of the steel container is said to be that it is intermodal and able to be transported by truck, rail, or ship without the cargo being handled at all. The savings from eliminating handling and the subsequent loss due to breakage and theft during transit has reduced the cost of goods everywhere.

The advantages of containerization are well understood today. Every port desires to have the most efficient container handling systems that are coordinated with rail lines and trucking depots. Indeed the low costs of global shipping continue to drop due to competition on all sides of the market.

The one issue that remains in the context of containerization is the volume required for end-to-end shipping. A forty or twenty-foot container holds far more than a single outlet can distribute to a local area, so these containers end their travel at large warehouses where their contents are unloaded and broken into volumes that can be absorbed by the local markets. In these situations, the issue of breakage, theft, and damage are the same as always.

The inefficiencies of distribution are related to the time between the container’s arrival and the complete distribution of its contents to local markets.

The Metapallet is a new approach to unionization and containerization, a breakthrough in logistics that can exploit other new technologies to create economies in every category of economic life. Economic opportunities related to manufacturing, distribution, storage, agriculture and real estate development are first, but social impacts are potentially greater as our society adopts new ways of life, changing our priorities to live longer as our networks of communities expand into orbital or deep space and subterranean tunnel and cavern systems.