Re-Thinking the Future

Urban design is a complex concept. Large-scale development by urban designers of an entire city or town considering the people, infrastructure, and necessary green pockets, that promote interaction of all these aspects harmoniously is what forms the basis of Urban design and planning. The impact of a successful urban plan belies its equally important aesthetic aspect. It controls people’s lifestyle, from the ease of daily commute to living sustainably with a small patch of greenery at every junction, maintaining an adequate built to un-built ratio are important considerations in Urbanism.

“By far the greatest and most admirable form of wisdom is that needed to plan and beautify cities and human communities.” –Socrates

In this article, we explore 10 influential urban designers throughout architectural history, who helped shape the world one neighborhood at a time.

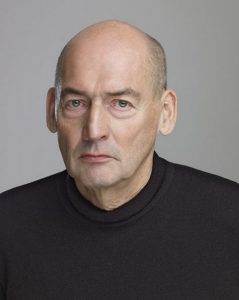

1. Rem Koolhaas | Urban Designers

The Future of The Way We Live, Love and Work

The Pritzker Prize laureate of 2000, a revolutionary Dutch Architect, Urban planner, Journalist, and Urban essayist, Rem Koolhas is an influential personality in the Architectural fraternity.

Alongside well-known projects like the Seattle Public Library, Euralille (an urban quarter in the center of Lille, France), Kunsthal (an exhibit space), Koolhas has published, “S, M, L, XL” a book that ended up becoming a Bible for Urbanists across the world, and “Delirious New York” which was then a best seller of Urban theory.

Alongside well-known projects like the Seattle Public Library, Euralille (an urban quarter in the center of Lille, France), Kunsthal (an exhibit space), Koolhas has published, “S, M, L, XL” a book that ended up becoming a Bible for Urbanists across the world, and “Delirious New York” which was then a best seller of Urban theory.

Thriving on constant change, uncertainty, and endless possibilities in a world of extremes that is open to every kind of human experience, Rem Koolhaas describes new urbanism as “the manipulation of infrastructure for endless intensifications and diversifications, shortcuts and redistributions – the reinvention of psychological space.”

©www.googleimages.comHe inspires the youth to never compromise on their designs, to challenge conventions, to compete, to present their thoughts to the world, to master their craft, to be original, to learn and develop eternally, to induce spatial planning, to be a visionary and most of all, to accept reality.

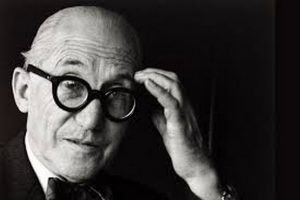

2. Le Corbusier | Urban Designers

Le Corbusier’s model city of Chandigarh

Recognized as the founding father of the Modernist movement, Le Corbusier was also an architect, designer, painter, urban planner, writer, and believed that, “Architecture is an economic and political tool that could be used to improve the world through the design of buildings and urban planning.” Steel and reinforced concrete along with clear forms and structures were the glories of his work.

Recognized as the founding father of the Modernist movement, Le Corbusier was also an architect, designer, painter, urban planner, writer, and believed that, “Architecture is an economic and political tool that could be used to improve the world through the design of buildings and urban planning.” Steel and reinforced concrete along with clear forms and structures were the glories of his work.

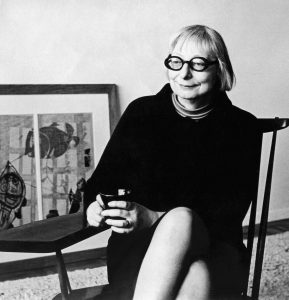

3. Jane Jacobs

Change how we build Cities

An author and an activist with no college degree or any formal training in urban planning, Jane Jacobs criticized experts in the male-dominated field of urban planning and she endured scorn from established figures. Her book “The Death and Life of Great American Cities” argued that urban renewal/ slum clearance did not respect the needs of city-dwellers and was not what the towns needed and focused on community-based approaches to planning.

An author and an activist with no college degree or any formal training in urban planning, Jane Jacobs criticized experts in the male-dominated field of urban planning and she endured scorn from established figures. Her book “The Death and Life of Great American Cities” argued that urban renewal/ slum clearance did not respect the needs of city-dwellers and was not what the towns needed and focused on community-based approaches to planning.

Jane organized protests to protect neighborhoods from slum clearance, particularly Robert Moses’ plans to outstrip her own “Greenwich Village” neighborhood. She views cities as ecosystems, mixed-use developments, bottom-up city planning opportunities, and local economies.

4. Kevin A. Lynch | Urban Designers

The Image of the City

An American urban planner and author, Lynch advocated mental mapping, which is a process of working on an individual’s perception. His works depicted a perceptual form of urban environments and his book, “The Image of the City” is a seminal work on the same. He worked towards mastering an improvement in the visual aesthetics of cities and his process of people receiving sensory inputs from their environments is still widely used in urban design studies and research today.

An American urban planner and author, Lynch advocated mental mapping, which is a process of working on an individual’s perception. His works depicted a perceptual form of urban environments and his book, “The Image of the City” is a seminal work on the same. He worked towards mastering an improvement in the visual aesthetics of cities and his process of people receiving sensory inputs from their environments is still widely used in urban design studies and research today.

According to Lynch, Path, Edge, Landmark, Node, and District along with Cleanliness of the streets, are the key elements that identify a particular city. He introduced concepts of ‘Place design’ and ‘Placemaking’ that are applicable today more than ever.

5. Janette Sadik- Khan

Change the Street, Change the World

Internationally acclaimed for her transformative redesigns of New York Citystreets and rapid implementation of urbanization strategies, Janette is a leading voice of the urban transportation policy. She has led one of the most radical revitalizations of the city’s streets in a half-century while being the Commissioner of the NYC Department of Transportation from 2007–2013.

Internationally acclaimed for her transformative redesigns of New York Citystreets and rapid implementation of urbanization strategies, Janette is a leading voice of the urban transportation policy. She has led one of the most radical revitalizations of the city’s streets in a half-century while being the Commissioner of the NYC Department of Transportation from 2007–2013.

She has been victorious in adding over 400 miles of bike lanes and the first parking-protected bike paths in North America while setting in motion more than 60 plazas across the city. Janette has sparked a massive economic recovery throughout the area with smooth flowing cities being her primary agenda.

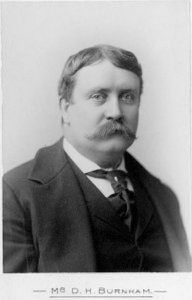

6. Daniel Burnham | Urban Designers

Daniel Burnham’s plan for Chicago

“Make no little plans; they have no magic to stir men’s blood and probably themselves will not be realized. Make big plans; aim high in hope and work, remembering that a noble, logical diagram once recorded will never die, but long after we are gonna be a living thing, asserting itself with ever-growing insistency. Remember that our sons and our grandsons are going to do things that would stagger us.” — Daniel Burnham

“Make no little plans; they have no magic to stir men’s blood and probably themselves will not be realized. Make big plans; aim high in hope and work, remembering that a noble, logical diagram once recorded will never die, but long after we are gonna be a living thing, asserting itself with ever-growing insistency. Remember that our sons and our grandsons are going to do things that would stagger us.” — Daniel Burnham

The most successful power broker the American architectural profession has ever produced, Daniel Burnham, was an American architect and urban designer. Burnham has been instrumental in contributing to the master plans of several cities, transforming the cityscapes of Chicago, downtown Washington D.C, Manila, and Baguio to name a few. Along with urbanization, he took an interest in designing skyscrapers and shopping centers.

7. Jan Gehl | Urban Designers

In search of the Human scale

Having given importance to urban pedestrian life, Jan Gehl, a Danish architect, and urban designer is prominent in creating “Cities for People.” He believes in systematic, gradual incremental improvements in a city. Gehl’s book “ Public Spaces, Public Life” describes how such incremental improvements have transformed Copenhagen from a car-dominated city to a more pedestrian-oriented, people’s city.

Having given importance to urban pedestrian life, Jan Gehl, a Danish architect, and urban designer is prominent in creating “Cities for People.” He believes in systematic, gradual incremental improvements in a city. Gehl’s book “ Public Spaces, Public Life” describes how such incremental improvements have transformed Copenhagen from a car-dominated city to a more pedestrian-oriented, people’s city.

Gehl is also committed to making cities, neighborhoods, and places where people have control over their health and wellbeing and are enabled to take meaningful, climate-conscious decisions within their daily lives.

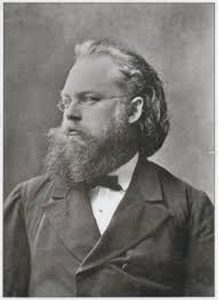

8. Camillo Sitte

Artistic limitations of modern city planning

A visual city planner, painter, and architect, Camillo Sitte drew inspiration from his travels around European towns and had striven to establish warmer and more welcoming spaces in the development of urban construction, planning, and regulation. His book “City Planning According to Artistic Principles” talks about creating spacious plazas, monumental and decorative features, and other complementary elements that draw a parallel between urban spaces and interiors of a room.

A visual city planner, painter, and architect, Camillo Sitte drew inspiration from his travels around European towns and had striven to establish warmer and more welcoming spaces in the development of urban construction, planning, and regulation. His book “City Planning According to Artistic Principles” talks about creating spacious plazas, monumental and decorative features, and other complementary elements that draw a parallel between urban spaces and interiors of a room.

Focusing on the importance of irregularity within an urban form, he challenged, among other things, a growing tendency toward rigid symmetry in contemporary urban design, the isolated placement of churches and monuments in large.

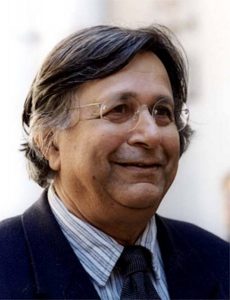

9. Raj Rewal

Break in India

Leaping ahead in the field of architecture and urban planning one project at a time, Raj Rewal has set global precedents by beautifully weaving Indian traditional heritage together with contemporary syntax, reflecting aptly his expression of culture and modern vocabulary. A play of scale and texture, rhythm and geometry, light modulations creating interconnected spaces, culminates to form his forte. He works towards promoting craftsmanship, new technology in the building industry, and climatic sensitivity.

Leaping ahead in the field of architecture and urban planning one project at a time, Raj Rewal has set global precedents by beautifully weaving Indian traditional heritage together with contemporary syntax, reflecting aptly his expression of culture and modern vocabulary. A play of scale and texture, rhythm and geometry, light modulations creating interconnected spaces, culminates to form his forte. He works towards promoting craftsmanship, new technology in the building industry, and climatic sensitivity.

His Asian games village, New Delhi, India, is the first of its kind settlement and is inspired by Jaiselmer’s urban fabric. This set a new dynamic to Delhi’s cityscape. The creation of narrow traditional streets links the housing units providing intimate encounters between people and a sense of belongingness to the neighborhood square.

He believes that contemporary architecture should take advantage of all the most advanced technologies that modernity has to offer.

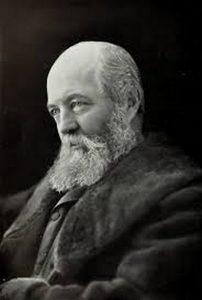

10. Fredrick Law Olmsted

Designing America

Proclaimed as the father of American Landscape Architecture, Olmsted has been instrumental in designing the famous Central Park in NYC. A good stroll through a park can be a remedy for any kind of stress and superficial lifestyle; was his belief and he designed to create vast recreational and cultural ecosystems in the heart of American cities. He was also involved in designing America’s first and oldest coordinated system of public parks and parkways in Buffalo, New York; the country’s oldest state park, the Niagara Reservation in Niagara Falls, New York; one of the first planned communities in the United States

Proclaimed as the father of American Landscape Architecture, Olmsted has been instrumental in designing the famous Central Park in NYC. A good stroll through a park can be a remedy for any kind of stress and superficial lifestyle; was his belief and he designed to create vast recreational and cultural ecosystems in the heart of American cities. He was also involved in designing America’s first and oldest coordinated system of public parks and parkways in Buffalo, New York; the country’s oldest state park, the Niagara Reservation in Niagara Falls, New York; one of the first planned communities in the United States

Being involved highly with the landscape, combining this greenery with the urban population is what his work attempted to establish.

Currently pursuing Architecture, Pallavi is in her final year of B.Arch. Being a passionate Architecture student,she’s developed a vast technical and hand-based skill-set. Finally, having had time this lockdown, she revoked her love for reading about the field which ultimately led her to believe that “Form does follow Function”.